technological successors: metal coating

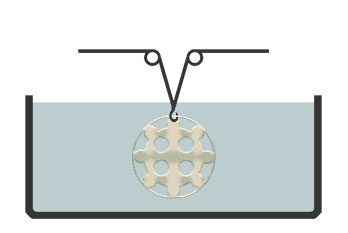

METAL COATED plastics are covered with a defined layer of a special copper and nickel mixture and have modified, especially desired characteristics. It is an expensive method which is not suitable for series production.

Scope for metal coating

sample, functional and design parts made with laser sintering from polyamide

SLA parts made from varying plastics

for very high standards regarding strength and stiffness

for the significant increase of the temperature resistance

for the improvement of electrical conductivity

for the improvement of thermal conductivity

for the prevention of plastic deformation under load

for the shielding against electromagnetic fields

for the resistance against aggressive and corrosive influences

as replacement for pressure die-casting parts

for a metallic appearance

for especially demanding design objects.

Attention – especially well-suited for single pieces.

Materials

Metallization is achieved by copper and nickel in variable volume proportions.

The properties of the composite components result directly from the ratio of the three components they contain.