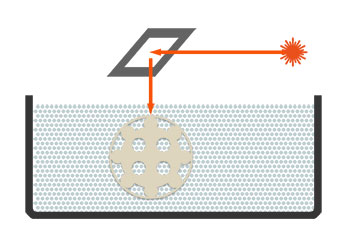

lasersintering sls

SELECTIVE LASER SINTERING (= SLS) is a generative manufacturing process that uses a laser beam to melt powdered material according to the specific shapes defined by a 3D CAD model, result is a solid structure.

It is one of the most productive and simultaneously most cost-effective processes and is used to create prototypes and small batch series.

What makes this so special is that, in contrast to conventional production processes, here it is possible to create very complex, three dimensional geometries – even with undercuts – within a fairly short time.

Scope for SLS

functional, durable, single pieces suitable for series production, prototypes and small batch series

Basic materials

Polyamide PA 2200 - unfilled, white - our standard

Polyamide PA 1101 - unfilled, white opaque, high flexible

Polyamide PA 12AL - filled, anthracite, grindable, high-grade haptics

Polyamide PA3200GB - filled, white, high regidity and high elongation at break

Polyamide PA FR2241 - flame-retardent polyamide

TPU - flexible, offwhite

Maschines

prodways ProMaker P1000

prodways laser sintering 3D printer

prodways laser sintering 3D printer

300mm x 300mm x 300mm build platform

The ProMaker P1000 plastic 3D printer offers industrial performance and high precision. Built parts show superior surface finish, made possible by a fine laser beam and a digital galvo scanning system. Like the other printers we use it for efficient small series production and parts with complex geometries.

EOSINT P 395

Lasersintering machine by EOS GmbH

Lasersintering machine by EOS GmbH

Assembly space 340mm x 340mm x 600mm

This machine ideally upgrades our portfolio of smaller SLS-machines and is fully comparable to our existing Formiga P 100-machines with regards to speed and quality.

EOS Formiga P 100

Lasersintering machine by EOS GmbH

Lasersintering machine by EOS GmbH

Assembly space 200mm x 250mm x 330mm

These machines are useful for economical production of small series and individual products with complex geometries and small dimensions. Furthermore these machines provide capacities for rapid and flexible prints of fully functional prototypes.