tool-bound technology: rim method

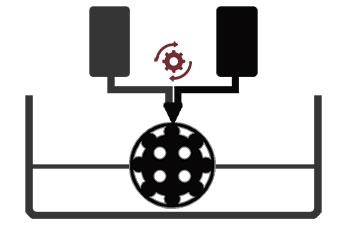

You need replicas? RIM method (=REACTION INJECTION MOULDING) means the mixture of two components polyurethane and the following injection in a CNC-machined mould. This procedure is well-suited for small and medium sized series production.

Scope for RIM-method

cost-effective and multiple copying of functional parts

Small batch series production with defined material characteristics

black parts

cost-effective for

reproduction of small up to big components with increased wall thicknesses with quantities between 10 and 1000

Materials

wide range of different polyurethanes with varying material characteristics and finishing options (lacquering, coating etc.)

Furthermore we offer a variant of the RIM procedure, the Reinforced Reaction Injection Moulding (RRIM-Verfahren). This method adds filler to the polyurethane – glass fiber (ca. 0,2mm), carbon fiber and rock flour – in order to provide the components with better stiffness values or to show less elongation at break.