stereolithography sla

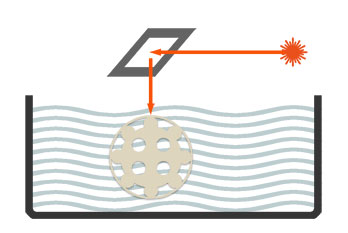

STEREO-LITHOGRAPHY (= SLA OR STL) is a form of additive manufacturing technology that creates parts in a layer by layer step using a process by which light causes chains of molecules to link together. The creation of highly complex geometrics – even with undercuts – is no problem, even though this is not possible with conventional production.

Scope for SLA

Design models and functional models with enhanced requirements regarding surface quality at low to medium mechanical stress and no thermal requirements (< 45°C)

Pieces of artwork

Master pattern for follow-up processes (vacuum casting, RIM)

On leaving the machine the components have a good, fairly smooth surface.

By appropriate finishing the components become very smooth and the transparent material becomes clear (after applying clear coat).

Post processing like lacquering or coating is particularly opportune.

Materials

Acrylic- und epoxy resin-based materials, in part with ceramic fillers, with variable mechanical and thermal properties in different shades:

clear, white and grey.

Accura® 25,

Accura® ClearVue,

Somos® EvoLVe,

Somos® GP Plus,

Somos® NeXt,

Somos® Perform / NanoTool

Maschines

SLA 5000 der 3D Systems GmbH

space 500 mm x 500 mm x 550 mm

SLA 7000 der 3D Systems GmbH

space 500 mm x 500 mm x 550 mm

STEREOS MAX 600 der EOS GmbH

space 600mm x 600 mm x 390 mm