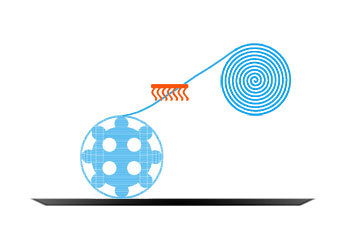

FUSED FILAMENT FABRICATION FFF is an additive manufacturing method whereby the component gets built from a melt processable plastic string. First the material gets punctiformed warmed up and then cured by cooling it down. Due to the method the producible wall thicknesses with a hollow body are restricted.

Scope for fff

cost-effective, big, voluminous models

cost-effective for

first product designs without undercuts

functional models

big parts with low complexity

lost molds with simple geometrics

Materials

different plastics

PP (Polypropylene)

ABS (Acrylnitril-Butadien-Styrol)

ABS (Acrylnitril-Butadien-Styrol)-EL

Arnitel® TPE (thermoplastic elastomere)

PA 6GF30 (Polyamide)

PA 666 (Polyamide)

PC (Polycarbonate)

PET (Polyethylene terephthalate)

PLA (Polylactic acid)

UltemTM 1010 (Polyetherimide)

UltemTM 9085 (Polyetherimide)

Machines

X400 CE

3D-Printer of German RepRap GmbH

space 400mm x 400mm x 350mm

Mit einer Schichtdicke von bis zu 0,1 mm und

einer großen Druckfläche lassen sich Modelle

bis zu einem Volumen von ca. 56 l drucken.

Es gehört sehr viel Erfahrung dazu, um mit Schmelzschicht-Druckern saubere Ergebnisse zu erzielen.